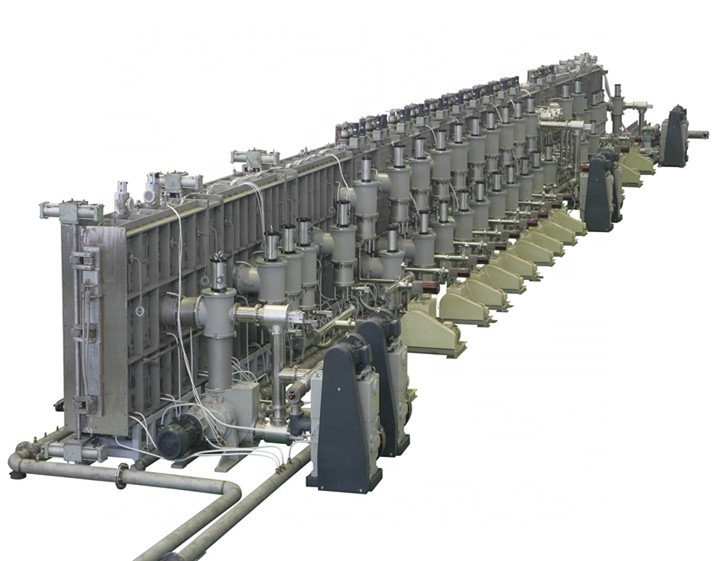

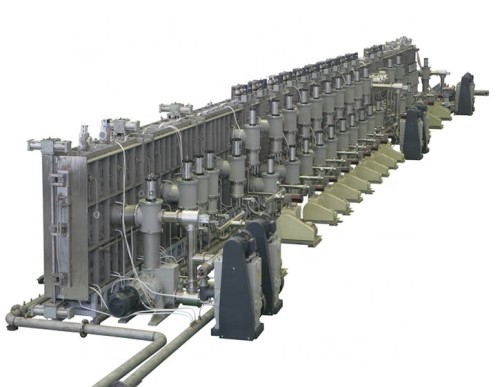

Plastic products Vacuum PVD coating machine

- Price

- US $150000

- Model

- Continuous Magnetron coating Production Line

- MOQ

- 1 piece

Item specifics

- progressing:60 day

- sample progressing:15 day

Review

Description

Vacuum evaporation coating machine for plastic product is mainly used for the surface of the rubber and plastic products, ceramics and glass etc. having been treated in a vapor-deposited

Vacuum evaporation coating machine for plastic product is mainly used for the surface of the rubber and plastic products, ceramics and glass etc. having been treated in a vapor-deposited

metal film (aluminum, chrome, stainless steel and other metals), colorful film, imitation gold film,resulting in bright, beautiful, inexpensive plastics, ceramics, surface metalization products etc. Widely used in arts and crafts, decoration decor, lamps, furniture, toys, bottle caps, female heel,automotive reflector, crafts, jewelry, shoes,watches, cell phones, DVD, MP3, PDA sheel, keys; cosmetics sheel; Christmas gifts and other industries. Processed materials include: ABS, PS, PP, PC, PVC, nylon, metal, glass, ceramics, TPU etc. Plating effect: ordinary plating glossy, matte (semimatte, all dumb), the electroplating process wrinkles, drawing, rain, colorful etc.